Responsible Sourcing

The life of our clothing begins well before any fabric is sourced or sewn. At each step along our supply chain, our values drive improvements in our practices.

OUR FACTORIES

How We Work with Factories

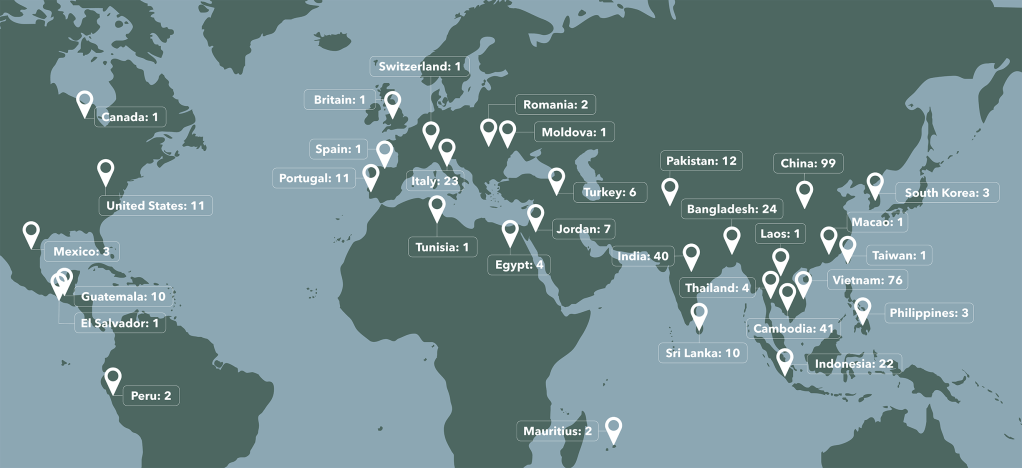

To make AEO products, we partner with apparel manufacturers that operate more than 300 factories in more than 20 countries around the world. We do not own or operate any factories, so it’s important to develop trusted relationships with our suppliers to make our apparel responsibly.We’re working to enhance our current factory monitoring programs and advance key initiatives that focus on worker well-being, environmental responsibility and increased supplier ownership

How We Source

In our supply chain, we value suppliers that share our commitment to responsibility and respect the safety and rights of their workers. We effectively promote relationships with these types of suppliers by first training our new sourcing associates to understand the importance of compliance in factories. With this base of understanding, our Responsible Sourcing team meets monthly with our Sourcing team to discuss the overall performance of our suppliers, including social compliance, and review any factories in our supply chain that are currently working to remediate noncompliance issues.

WHAT WE STAND FOR

SAFETY

Supplier Code of Conduct

AEO is dedicated to the highest level of social responsibility. As part of that commitment, we direct our business relationships to those suppliers, including our sourcing agents, vendors, factories and their own suppliers, who share our vision of ethical and fair working conditions.

Factory Fire + Building Safety

All of our strategic factories are required by AEO to comply with national building requirements and fire codes and have training for their workers on safe workplace practices.

Factory Inspection + Improvement

All of the apparel factories we actively source from are visited and inspected every year by our internal team or third-party auditing partners. These audits are based on our Supplier Code of Conduct and go beyond the basic requirements outlined there. Audits are also customized around particular country or region risks to focus on specific topics, like health and safety or migrant workers. Audits may include extra worker interviews if needed, whether those conversations take place onsite or offsite, and include worker accommodation where applicable.

Key Sourcing Policies

Great style shouldn’t come at the cost of the welfare of others. The materials and treatment processes we use are one part of our commitment to responsible sourcing, reflecting our company values and reinforcing our Code of Conduct.

WORKERS’ VOICE +

WOMEN’S EQUITY

Responsible Recruitment

We are committed to working with factories that treat all workers with respect, and take special precautions for vulnerable populations, such as those that migrate for work.

Focus on Workers’ Voice

We are committed to working with our factories to foster an environment in which workers feel comfortable raising and discussing labor concerns in a constructive manner.

Improving Women Factory Workers’ Health

We are committed to promoting the health and well-being of the women who make our products in our global supply chain. Our goal is for all strategic factories to invest in women